A VALUABLE INVESTMENT

Invest in our solutions,

and let the project pay for itself

At Exodraft, we specialise in designing custom solutions that should be seen as a long-term investment with high value. The project often pays for itself after 2-3 years.

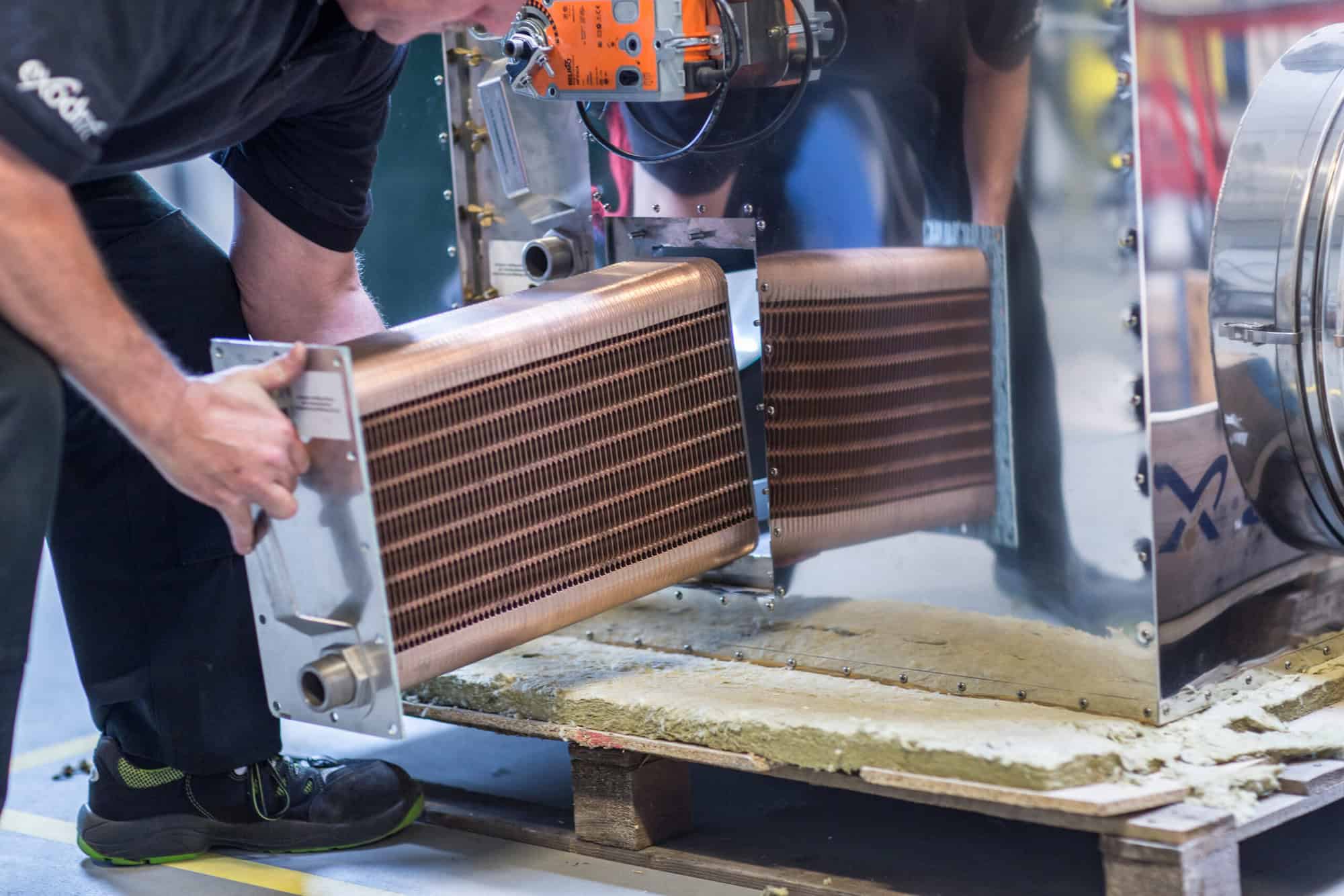

We have great respect for your business, and therefore it is important to us that our solutions do not compromise it. On the contrary, our chimney fans increase combustion efficiency and reduce energy waste. Additionally, our heat recovery systems enable you to utilize up to 95% of the excess heat from production elsewhere in the company. This way, you are also less affected by fluctuating fuel prices.

Drink and food industry

Bakeries

We help both large and small bakeries with efficient chimney fan systems and heat recovery.

Coffee roasteries

We assist industrial coffee roasteries in reusing waste heat from the roasting process.

Juice & cider production

We help juice and cider producers reuse their waste heat in the production process.

Dairies

We offer heat recovery and draught control for dairies to recycle waste heat.

Breweries & distilleries

We assist breweries and distilleries with heat recovery and mechanical draught control.

Slaughterhouses

We provide heat recovery systems to slaughterhouses to maximise the use of waste heat.

Food manufacturing

Reuse waste heat from production processes such as baking and fermentation.

Light and heavy industry

Hardening plants

We offer heat recovery systems and mechanical draught control for hardening plants.

Paper mills

Recycle waste heat from processes such as pulp production, reusing up to 95% of the heat.

Can manufacturing

Our heat exchangers can convert heat from processes like aluminium refining into hot water.

Automotive industry

We provide solutions for heat recovery and mechanical draught control in the automotive industry.

Metal processing

Recycle waste heat from processes such as melting, casting, and welding.

Paint & drying plants

Our systems can recover up to 95% of waste heat from processes like paint hardening.

Foundries

We assist foundries in reducing energy consumption and CO₂ emissions.

Glass production

With temperatures up to 1550°C, we help glass producers with heat recovery.

Cement production

We help recover heat from the heating of raw materials in cement production.

Aluminium industry

We help utilise waste heat in further production or for district heating.

OPTIMIZE YOUR ENERGY PRODUCTION

Reduce your CO₂-

emission and costs

As a result of the increasing focus on reducing CO₂ emissions, many companies are experiencing heightened regulatory requirements in this area. At Exodraft, we are proud to help our industrial customers reduce their CO₂ footprint with our heat recovery systems, chimney fan systems, and stove filters.

In addition to our chimney fans reducing energy waste and increasing fuel utilisation, our heat recovery systems ensure that you can reuse excess heat from your production.

take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recover my waste heat?

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes..

Why heat recovery is important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

Download data sheets

exodraft